Macarbox LUX Laser Cutting machine is now fully operational in Germany

VG Schoepe Berlin, a leading German display producer and part of the Van Genechten International Packaging Group, set out to execute an ambitious goal: achieve a 100% digital production strategy.

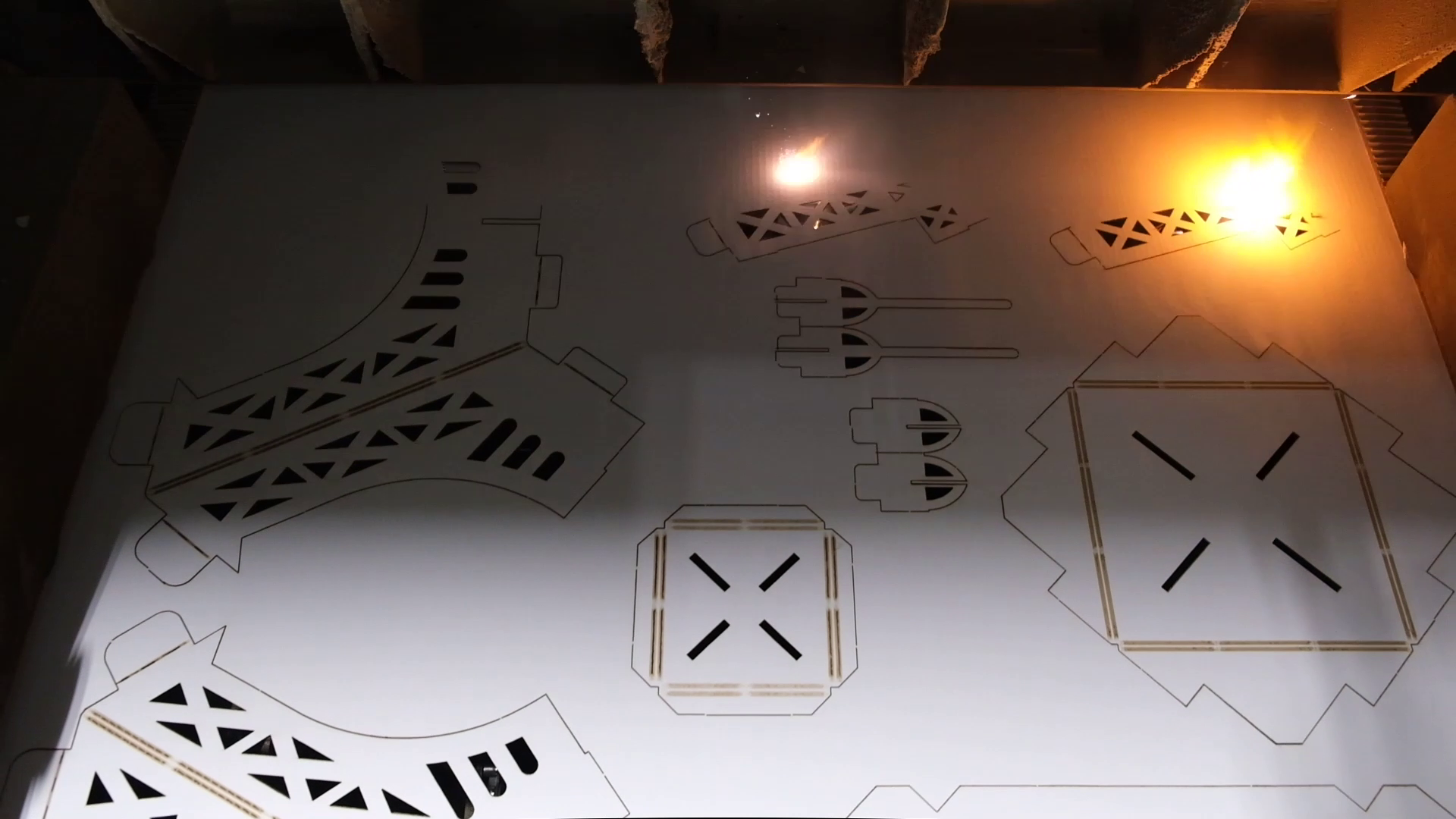

To make this a reality and effectively eliminate the logistical burdens and costs associated with analog tooling, they partnered with Macarbox, culminating in the installation of a LUX Laser Cutting Machine at their plant in early 2025.

Verified results and operational impact

The installation quickly demonstrated its effectiveness, transforming key operational metrics:

-

Production duration was cut from approximately two weeks down to less than a week.

-

We achieved zero change overtime between new designs, eliminating the costs and delays associated with analog tooling.

-

The cutting process did not affect the thickness of the board, ensuring that full strength remained.

-

The large format capacity (up to 1.60 x 3.50 m) allowed for the production of large items on one sheet without gluing any parts together.

A reliable solution supporting the digital future

The partnership has delivered a fully reliable and operational machine, crucial for VG Schoepe’s strategic goals. According to Managing Partner Andreas Grathwohl, “The LUX machine provides the flexibility to support our digital strategy business model in a perfect manner”.

Are you ready to explore how LUX technology fits your operation? Take a look at how they did it in Germany here.

🎥 Watch the video